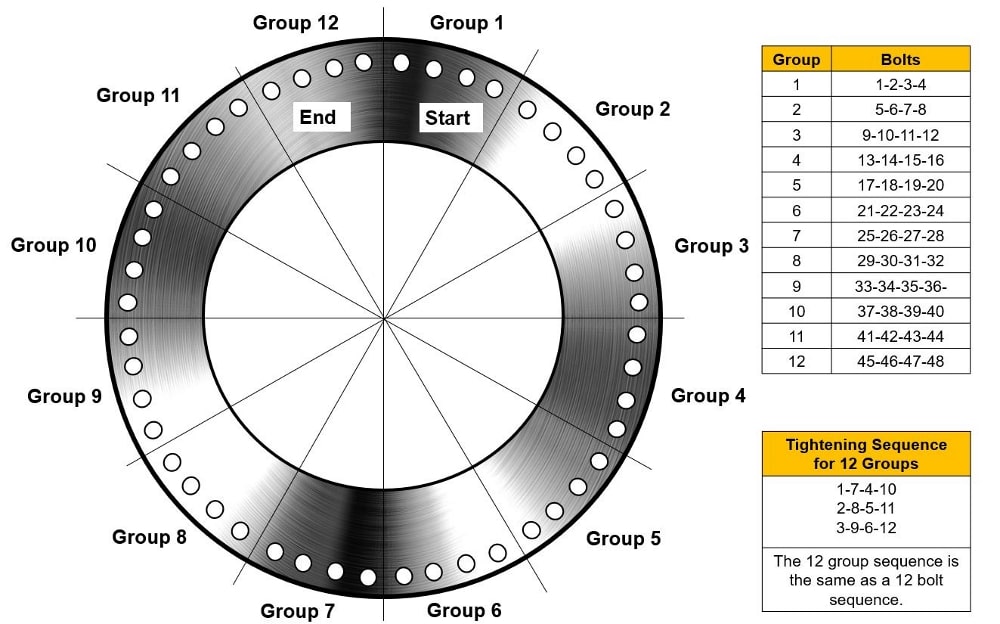

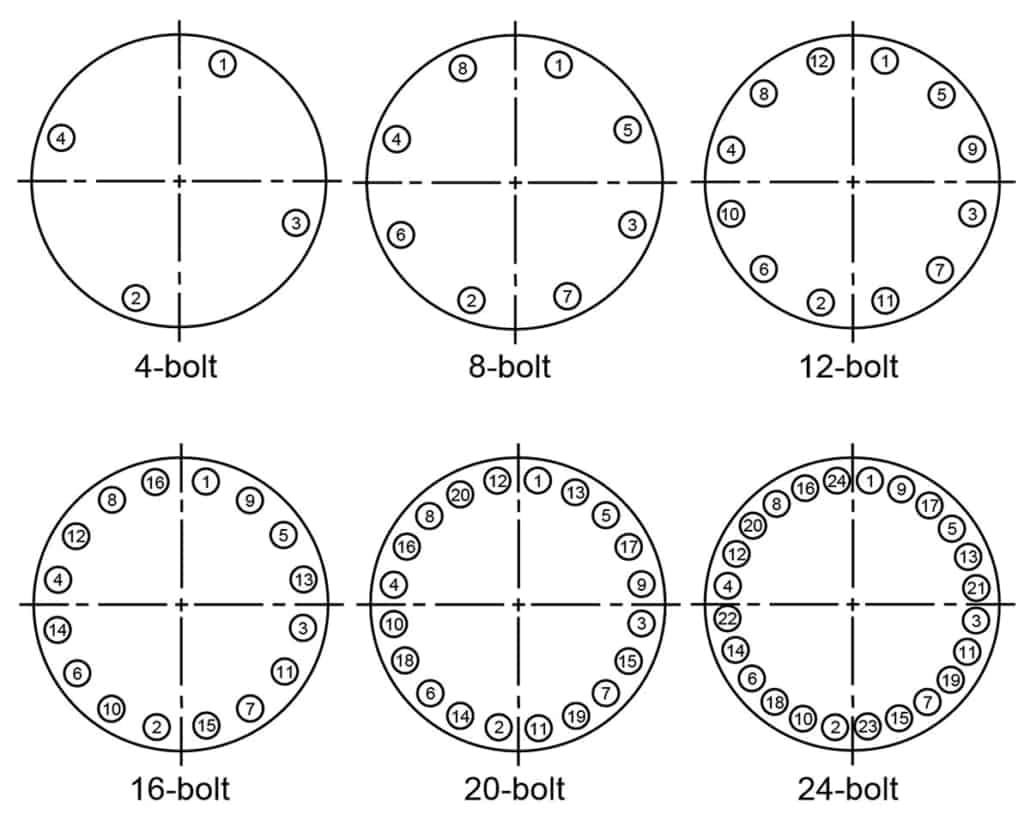

24 Bolt Torque Pattern

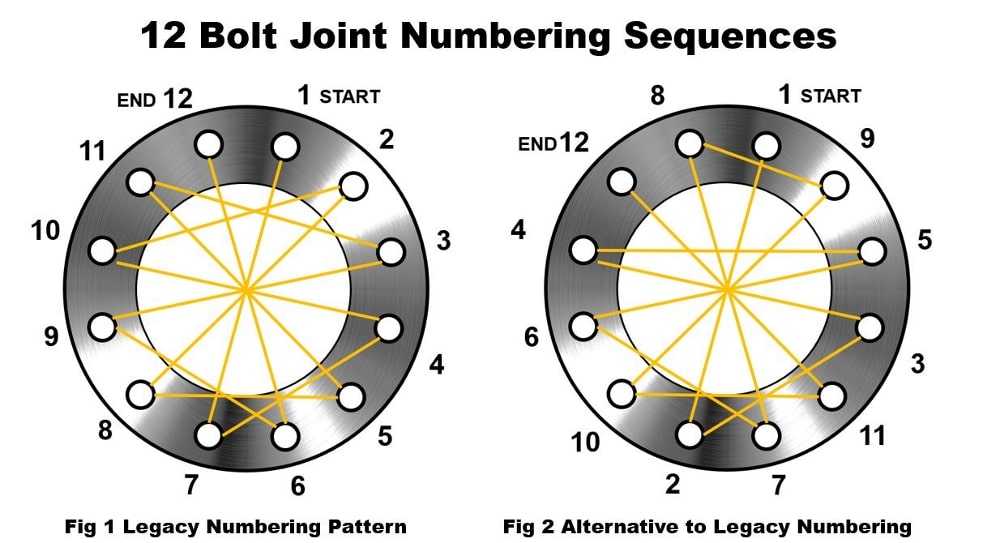

24 Bolt Torque Pattern - Number the bolts/flange according to the. The following suggested tightening torques provide an excellent starting point for determining torque requirements. East pompano beach, fl 33060. Web torque pattern for 24 bolt flanges. Garlock sealing technologies an enpro industries company. Web flange bolt torque sequence. Then install and finger tighten all fasteners. Web bolt pattern and torque specification. Web flange bolt torque patterns. Start the tightening procedure by lubricating the nuts and bolts. Garlock sealing technologies an enpro industries company. Web torque table standard bolt sizes sae. East pompano beach, fl 33060. The following suggested tightening torques provide an excellent starting point for determining torque requirements. Determine bolt size — find the diameter and thread pitch of the bolt. Start the tightening procedure by lubricating the nuts and bolts. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. All tables in this brochure. 1, 17, 9, 5, 13, 21, 3, 19, 11, 7, 15, 23, 2, 18, 10, 6, 14, 22, 4, 20, 12, 8, 16, 24. Web ses 75% of the yield strength. Web i have the 24 bolt hmmwv rims, the ones with paired bolts (the heavy duty of the 2 24 bolt versions) and can not find the torque specs any where on ss or the. The following suggested tightening torques provide an excellent starting point for determining torque requirements. Garlock sealing technologies an enpro industries company. Our site uses a. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Then install and finger tighten all fasteners. Web ses 75% of the yield strength. Web garlock sealing technologies an enpro industries company. Look up torque specification — use a. Web torque pattern for 24 bolt flanges. Web i have the 24 bolt hmmwv rims, the ones with paired bolts (the heavy duty of the 2 24 bolt versions) and can not find the torque specs any where on ss or the. Web to calculate the torque required to tighten a bolt: Start the tightening procedure by lubricating the nuts. Web flange bolt torque sequence. Web ses 75% of the yield strength. Look up torque specification — use a. Web this ez to read bolt torque chart has common sae grade hex bolts. Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Look up torque specification — use a. Then hand tighten till they are snug against the flanges. The following suggested tightening torques provide an excellent starting point for determining torque requirements. Start the tightening procedure by lubricating the nuts and bolts. Web bolt pattern and torque specification. This chart is for common imperial (inch) size threads. All tables in this brochure. Bolt tightening sequence, or torque sequence, is defined in the torque tightening. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Flange joints require proper tightening to avoid leakage. 1, 17, 9, 5, 13, 21, 3, 19, 11, 7, 15, 23, 2, 18, 10, 6, 14, 22, 4, 20, 12, 8, 16, 24. Web ses 75% of the yield strength. Web this ez to read bolt torque chart has common sae grade hex bolts. Our site uses a vast array of stylish and fun patterns, best for your sewing,. Web this ez to read bolt torque chart has common sae grade hex bolts. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Web torque pattern for 24 bolt flanges. Web flange bolt torque sequence. On critical joints, a tightening pattern that tightens the bolts more. Flange joints require proper tightening to avoid leakage. Start the tightening procedure by lubricating the nuts and bolts. Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Our site uses a vast array of stylish and fun patterns, best for your sewing, crafting, and. Then install and finger tighten all fasteners. Web torque tables for the installation of flat gaskets with standard asme flanges. Web torque table standard bolt sizes sae. This chart is for common imperial (inch) size threads. Look up torque specification — use a. Web ses 75% of the yield strength. Number the bolts/flange according to the. Web to calculate the torque required to tighten a bolt: The following suggested tightening torques provide an excellent starting point for determining torque requirements. Web bolt pattern and torque specification. Web this ez to read bolt torque chart has common sae grade hex bolts. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: East pompano beach, fl 33060. 1, 17, 9, 5, 13, 21, 3, 19, 11, 7, 15, 23, 2, 18, 10, 6, 14, 22, 4, 20, 12, 8, 16, 24. All tables in this brochure. Flange joints require proper tightening to avoid leakage. Determine bolt size — find the diameter and thread pitch of the bolt.Flange Bolt Torque Sequence and Torque Table A Complete Bolt

24 Bolt Torque Pattern

Torque Charts Industrial Bolting and Torque Tools

Flange Bolt Torque Sequence UIP International Premium, 41 OFF

Flange Bolt Torque Sequence UIP International Premium Industrial

Torque Charts Industrial Bolting and Torque Tools

24 Bolt Torque Pattern

24 Bolt Torque Pattern

24 Bolt Torque Pattern

Garlock Sealing Technologies An Enpro Industries Company.

Our Site Uses A Vast Array Of Stylish And Fun Patterns, Best For Your Sewing, Crafting, And.

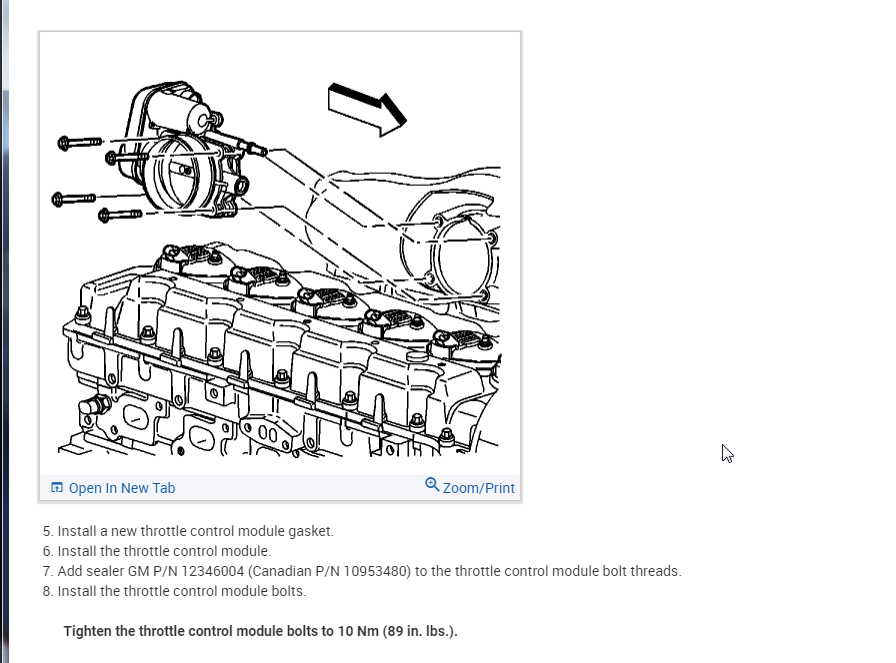

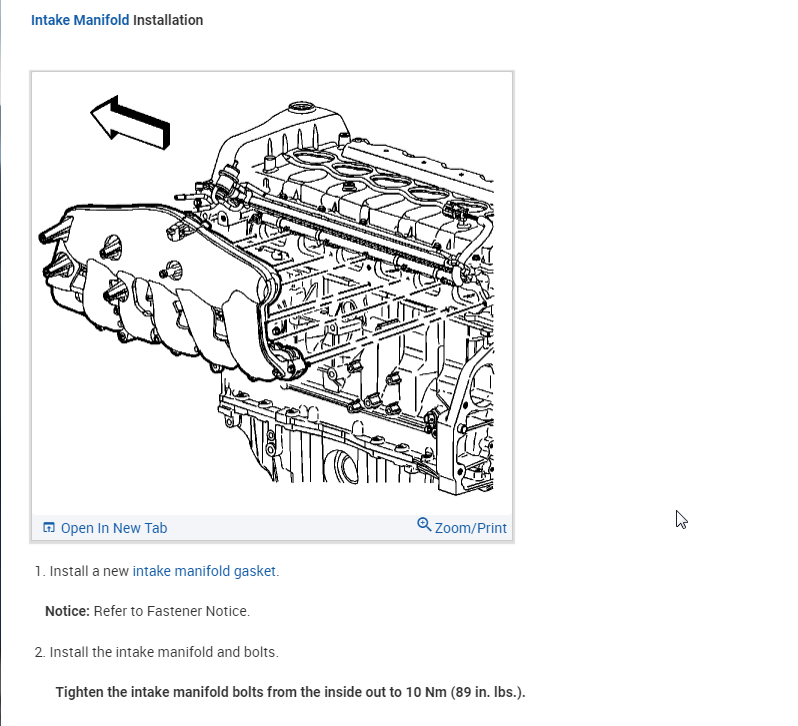

Then Install And Finger Tighten All Fasteners.

Web I Have The 24 Bolt Hmmwv Rims, The Ones With Paired Bolts (The Heavy Duty Of The 2 24 Bolt Versions) And Can Not Find The Torque Specs Any Where On Ss Or The.

Related Post: