Differential Gear Pattern

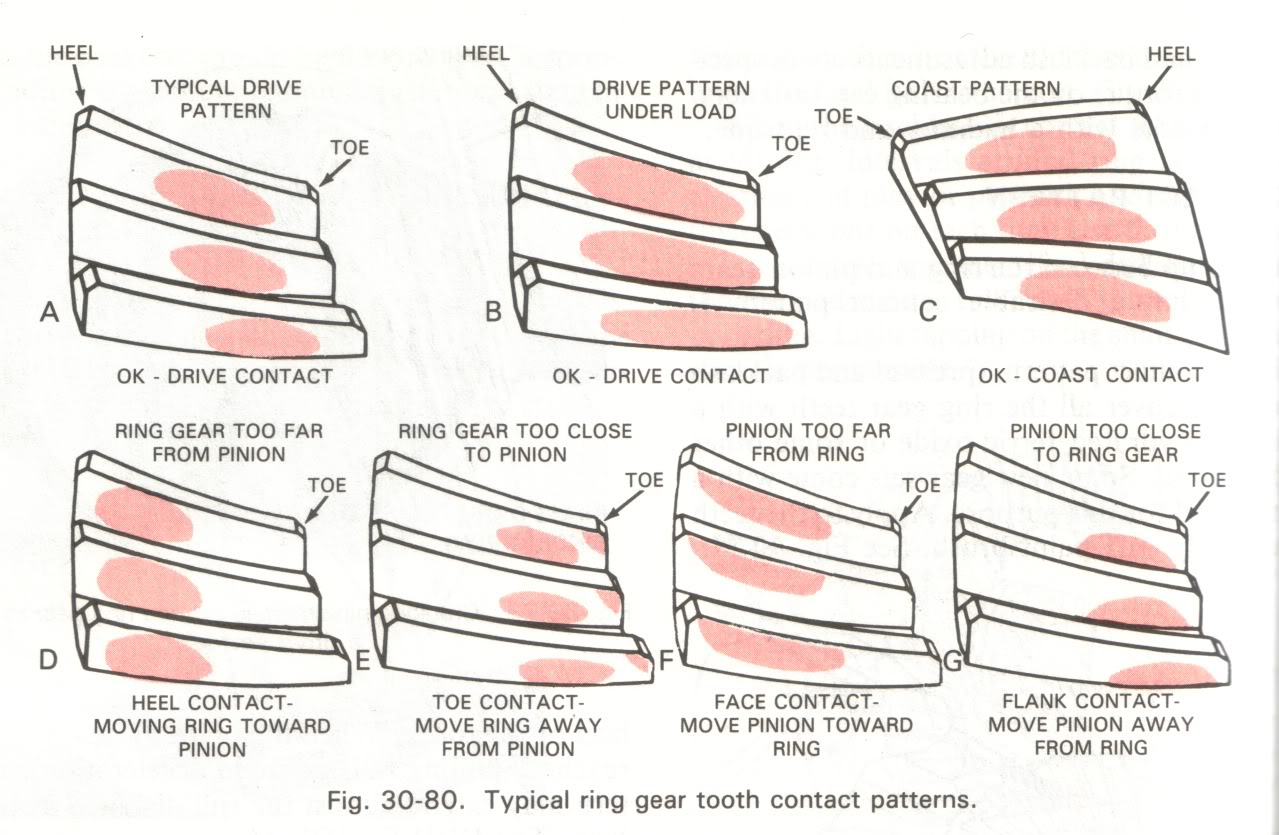

Differential Gear Pattern - As noted by west coast differentials The coast pattern will move deeper toward the tooth flank and slightly toward the heel. Web the heel of the gear tooth is the portion of the tooth surface at the outer end. He also explains how limited slip differentials get you out of the mud. Web the pattern refers to how the ring gear and pinion gears mesh. Web the toe of the gear tooth is the portion of the tooth surface at the end towards the center. Below is a gear ratio chart showing what your engine rpms would be at 65 mph based on your tire diameter and differential gear ratio in third gear (1:1 transmission ratio). ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. Every gear has a characteristic pattern. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Clean all new and used parts with clean solvent. In this video we give a quick d. The illustrations show typical patterns only, and explains how patterns shift as gear location is changed. Web the pattern refers to how the ring gear and pinion gears mesh. These differential installation instructions are provided online as a further convenience to the differential installer. Web every sierra gear & axle master differential installation kit (ik) comes with a printed differential installation and setup guide. Pattern adjustment cause & effect. Web see how to set up a ring and pinion gear set. Web in general, pattern movements can be summarized this way: Pulling off a proper differential. Clean all new and used parts with clean solvent. The top land of a gear tooth is the surface of the top of the tooth. Web every sierra gear & axle master differential installation kit (ik) comes with a printed differential installation and setup guide. Go slow and pay attention to details. The procedure involves changing the pinion position via. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. The heel of the gear tooth is the portion of the tooth surface at the outer end. Web the toe of the gear tooth is the portion of the tooth surface at the end towards. The heel of the gear tooth is the portion of the tooth surface at the outer end. In this video we give a quick d. Use shims to move the ring gear closer to the pinion to decrease backlash. Use shims to move the ring gear closer to the pinion to decrease backlash. As noted by west coast differentials Pattern adjustment cause & effect. Every gear has a characteristic pattern. Use shims to move the ring gear closer to the pinion to decrease backlash. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the toe. The tables on page 18 can be used to write down shim. These differential installation instructions are provided online as a further convenience to the differential installer. The top land of a gear tooth is the surface of the top of the tooth. Go slow and pay attention to details. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long. These differential installation instructions are provided online as a further convenience to the differential installer. Pattern adjustment cause & effect. Use shims to move the ring gear closer to the pinion to decrease backlash. Web one of the most common questions we're asked is how to properly read contact pattern markings during differential gear setup. ( gear tooth contact pattern. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. The coast pattern will move deeper toward the tooth flank and slightly toward the heel. Web one of the most common questions we're asked is how. The order in which adjustments are made during differential assembly and setup are: As noted by west coast differentials Clean all new and used parts with clean solvent. Web five cut ring & pinion gears (face milled): Web every sierra gear & axle master differential installation kit (ik) comes with a printed differential installation and setup guide. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Pattern adjustment cause & effect. These differential installation instructions are provided online as. ( gear tooth contact pattern )in this video i'm going to show you how to correctly read a differ. Pattern adjustment cause & effect. Every gear has a characteristic pattern. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing. Pulling off a proper differential setup comes down to. Engine rpms, vehicle speed, and tire diameter. Web gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Pattern adjustment cause & effect. Web the toe of the gear tooth is the portion of the tooth surface at the end towards the center. Web in general, pattern movements can be summarized this way: Below is a gear ratio chart showing what your engine rpms would be at 65 mph based on your tire diameter and differential gear ratio in third gear (1:1 transmission ratio). The tables on page 18 can be used to write down shim combinations and results. Web the heel of the gear tooth is the portion of the tooth surface at the outer end. The top land of a gear tooth is the surface of the top of the tooth. Use shims to move the ring gear closer to the pinion to decrease backlash. Web in this video, corey describes how differential gears work. The order in which adjustments are made during differential assembly and setup are: Pulling off a proper differential. Web there are three elements involved in determining the best gear ratio: The top land of a gear tooth is the surface of the top of the tooth.Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Differential Gear Patterns

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

How To Create & Read Ring Gear Patterns

Differential Paint Patterns Patterns Kid

Differential Installation Instructions West Coast Differentials

Fig. 1 Drive Axle Gear Tooth Pattern s

Differential Installation Instructions West Coast Differentials

Ring Pinion Pattern Patterns Gallery

Ring And Pinion Patterns

Expect To Perform An Initial Test Fitting And Adjustment Prior To Final Setup.

Go Slow And Pay Attention To Details.

Moving The Pinion Gear Closer To The Carrier Will Move The Drive Side Pattern Closer To The Flank And Slightly Toward The Toe.

As Noted By West Coast Differentials

Related Post: