Flux Core Welding Pattern

Flux Core Welding Pattern - The flux acts as a shielding agent, protecting the weld from contamination and producing cleaner, stronger welds. This process works by creating an arc between the metal electrode and the metal workpiece, creating a heat that melts the metal, which allows it to be fused. Welcome back to ac designs garage! Web couple tips and tricks to making your flux cored arc welding (fcaw) or gasless mig welds looking awesome! For these reasons, it makes sense to switch to the mig process for indoor welding. Web flux core is an arc welding process that uses heat generated by welding arc to fuse metals. Web flux core welding is a versatile and popular welding technique that utilizes a hollow wire electrode filled with flux. Web core, with a coil maximum outside diameter of 59.5 inches (151.13 cm), with a maximum of one weld (identified with a paper flag) per coil, with a surface free of scratches, holes, and rust. 2.3m views 8 years ago. Next, the workpiece is prepared by cleaning any contaminants off the surface. Web what is the process for flux core welding? This is essential when working on things like machine parts. Maximum force before failure, measured in psi or mpa. • electrolytically tin coated steel having differential coating with 1.00 pound/base box equivalent on the heavy side, with varied Web our 7 tips & tricks for beginner flux core welding 1. There are some safety measures which you should take for your own safety. Web to weld with flux core, you must set the welding machine to direct current electrode negative (dcen). We're navigating the nuances of using 0.30 flux core wire on a 3/16 t joint. But to enjoy its features, you will have to use the right flux core settings. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. This is an important step because most wire feed welders are default set to direct current electrode positive (dcep) for mig welding. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. Web flux core is an arc welding process that uses heat generated by welding arc to fuse metals. Web. Next, the workpiece is prepared by cleaning any contaminants off the surface. Web core, with a coil maximum outside diameter of 59.5 inches (151.13 cm), with a maximum of one weld (identified with a paper flag) per coil, with a surface free of scratches, holes, and rust. It is particularly useful for welding in outdoor or windy conditions, where shielding. This is essential when working on things like machine parts. But to enjoy its features, you will have to use the right flux core settings. This is an important step because most wire feed welders are default set to direct current electrode positive (dcep) for mig welding. This means that 2/3 of the heat in the arc will be directed. Web flux core welding is a versatile and popular welding technique that utilizes a hollow wire electrode filled with flux. Lets learn the basics to flux core welding! Web join bob from franken fab as he learns the basics of flux core welding with paul. Maximum force before failure, measured in psi or mpa. The flux acts as a shielding. We're navigating the nuances of using 0.30 flux core wire on a 3/16 t joint. Make sure your polarity is correct. It also tends to produce welds that aren’t as visually attractive as mig welds. The flux core within the tubular electrode is heated by an electric arc to. Flux core welding is used to weld thicker metals. Ready to join the welding. This is essential when working on things like machine parts. This is an important step because most wire feed welders are default set to direct current electrode positive (dcep) for mig welding. Today, let's explore the intricate world of mastering flux core welding. We're not just diving into the technique; Web what is the process for flux core welding? Flux core welding is used to weld thicker metals. We're navigating the nuances of using 0.30 flux core wire on a 3/16 t joint. Industrial flux core welds must meet specific tensile and yield strength requirements to ensure durability. Web flux core welding (fcw) is a welding process that uses a. It will continue to remain relevant on account of its high deposition rate and ability to join thick metal sections efficiently. Lets learn the basics to flux core welding! We're not just diving into the technique; Maximum force before failure, measured in psi or mpa. Web flux core welding is a versatile and popular welding technique that utilizes a hollow. There are some safety measures which you should take for your own safety. Web flux core welding: Web flux core welding is a versatile and popular welding technique that utilizes a hollow wire electrode filled with flux. Web strength standards in industry. For these reasons, it makes sense to switch to the mig process for indoor welding. Ready to join the welding. For these reasons, it makes sense to switch to the mig process for indoor welding. It also tends to produce welds that aren’t as visually attractive as mig welds. First, the welding machine is set up with the appropriate voltage and wire feed speed. To enhance both the aesthetic appeal and durability of your welds. Web flux core welding is a versatile and popular welding technique that utilizes a hollow wire electrode filled with flux. Web to weld with flux core, you must set the welding machine to direct current electrode negative (dcen). • electrolytically tin coated steel having differential coating with 1.00 pound/base box equivalent on the heavy side, with varied Industrial flux core welds must meet specific tensile and yield strength requirements to ensure durability. Web flux core is an arc welding process that uses heat generated by welding arc to fuse metals. This means that 2/3 of the heat in the arc will be directed toward the wire. This is an important step because most wire feed welders are default set to direct current electrode positive (dcep) for mig welding. We're navigating the nuances of using 0.30 flux core wire on a 3/16 t joint. Web couple tips and tricks to making your flux cored arc welding (fcaw) or gasless mig welds looking awesome! For these reasons, it makes sense to switch to the mig process for indoor welding. It uses a tubular wire filled with flux to facilitate the welding process. As the filler metal melts, it fuses the two. Welcome back to ac designs garage! Web flux core welding is used for welding mild steel and low alloy steel, typically used in construction, automotive, and manufacturing applications. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. As a result, you don't need to use a shielding gas, meaning you can flux core welding to.Dual Shield Flux Core Basics

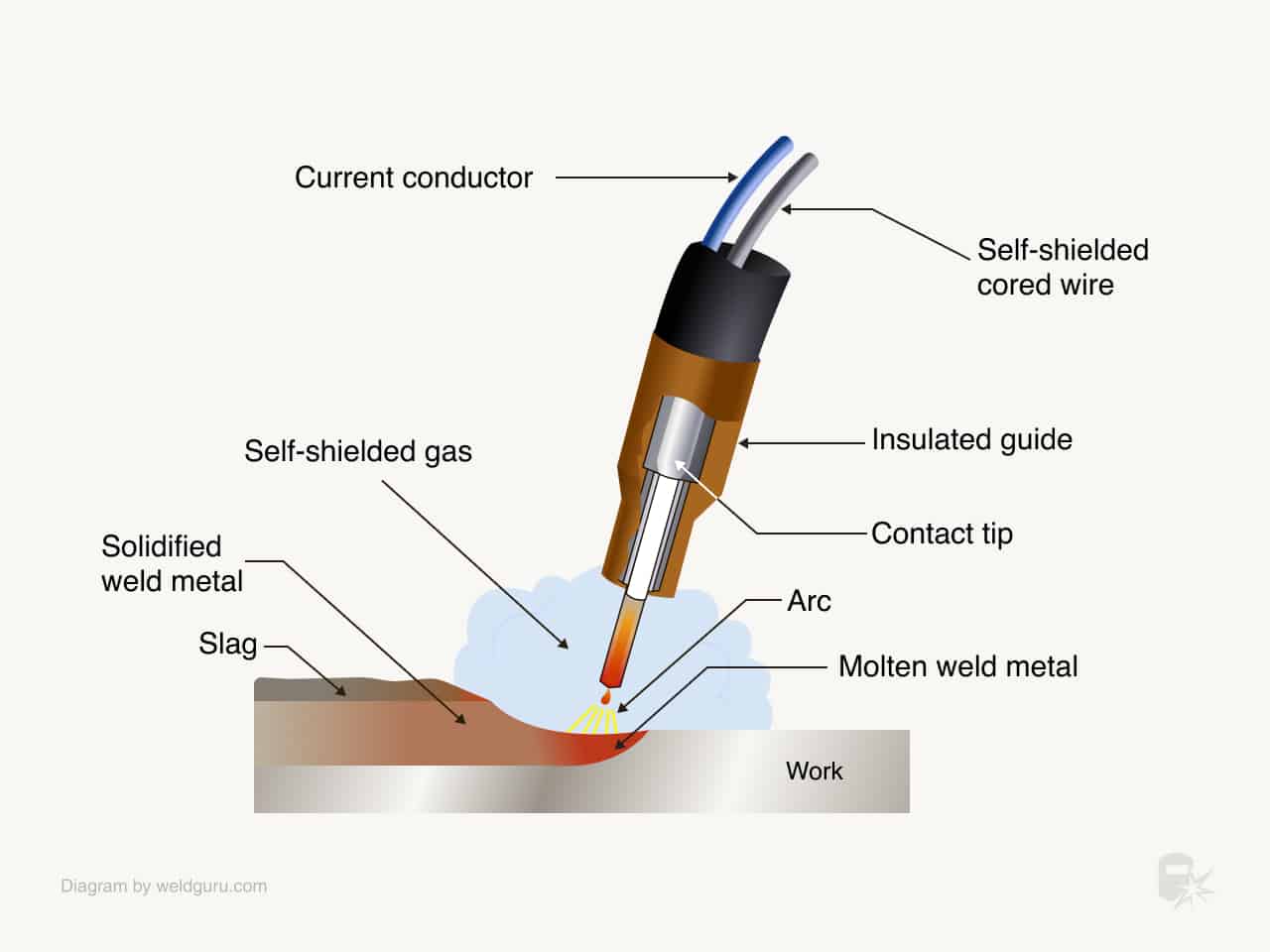

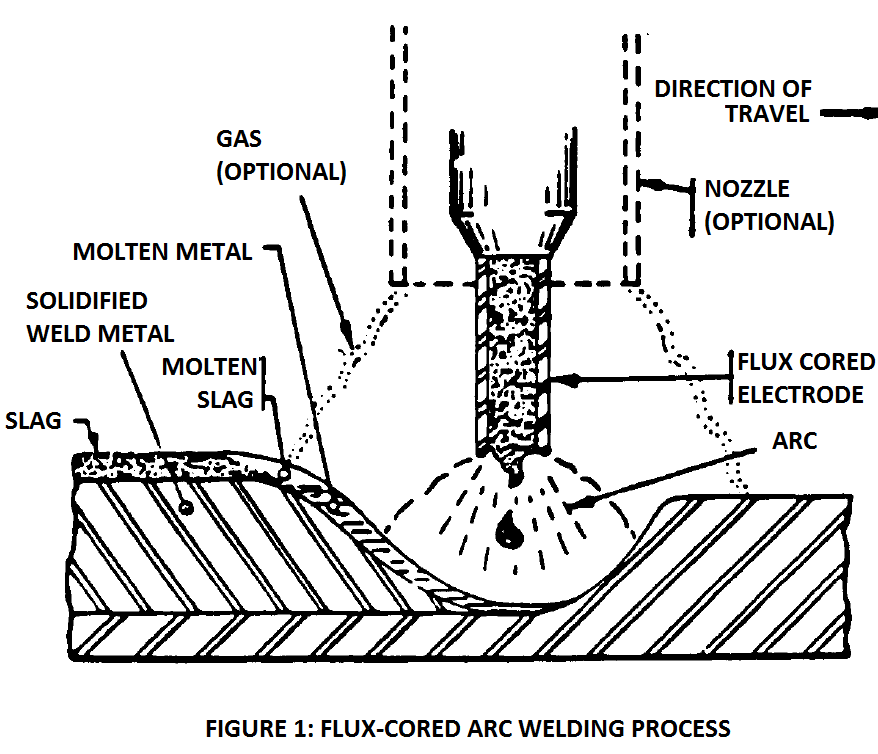

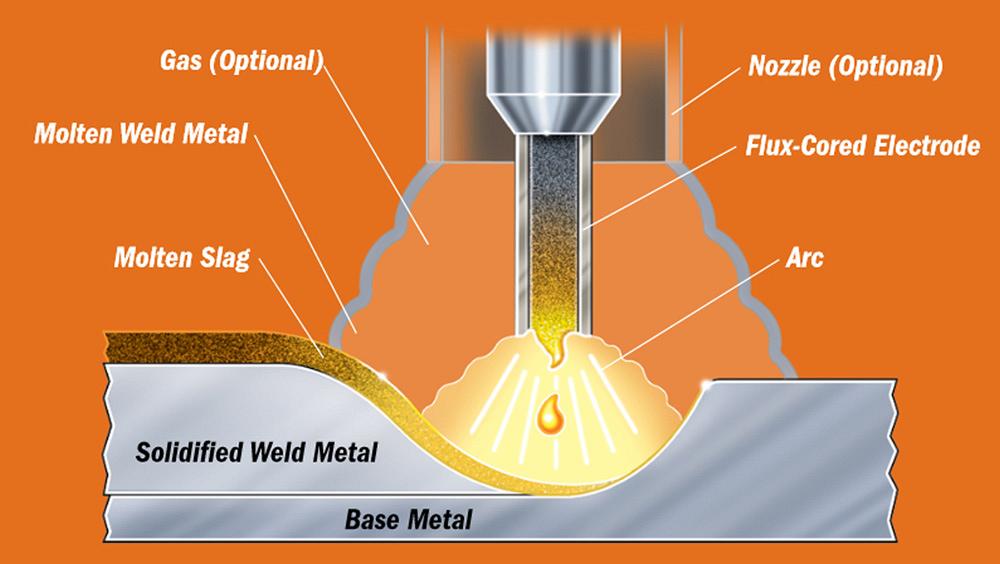

What is FluxCore Arc Welding (FCAW) & How Does it Work?

PPT Flux Cored Arc Welding (FCAW) PowerPoint Presentation ID518171

FluxCored Arc Welding Equipment

Vertical up fluxcore weave! 25.0v 275wire r/Welding

Welding Common Joints Using Flux Cored YouTube

Getting to Know Fluxcored Wires The Fabricator

Welding Straight VS Weaving Or Wave Flux Core Welding For Beginners

Did this a while back in class but this was one of my first fluxcore

How To Weld Vertical Or Upwards For Beginners Gasless Flux Core

Web Flux Core Welding:

This Is Essential When Working On Things Like Machine Parts.

There Are Some Safety Measures Which You Should Take For Your Own Safety.

Force Limit Before Permanent Deformation.

Related Post: