Gear Contact Pattern Paint

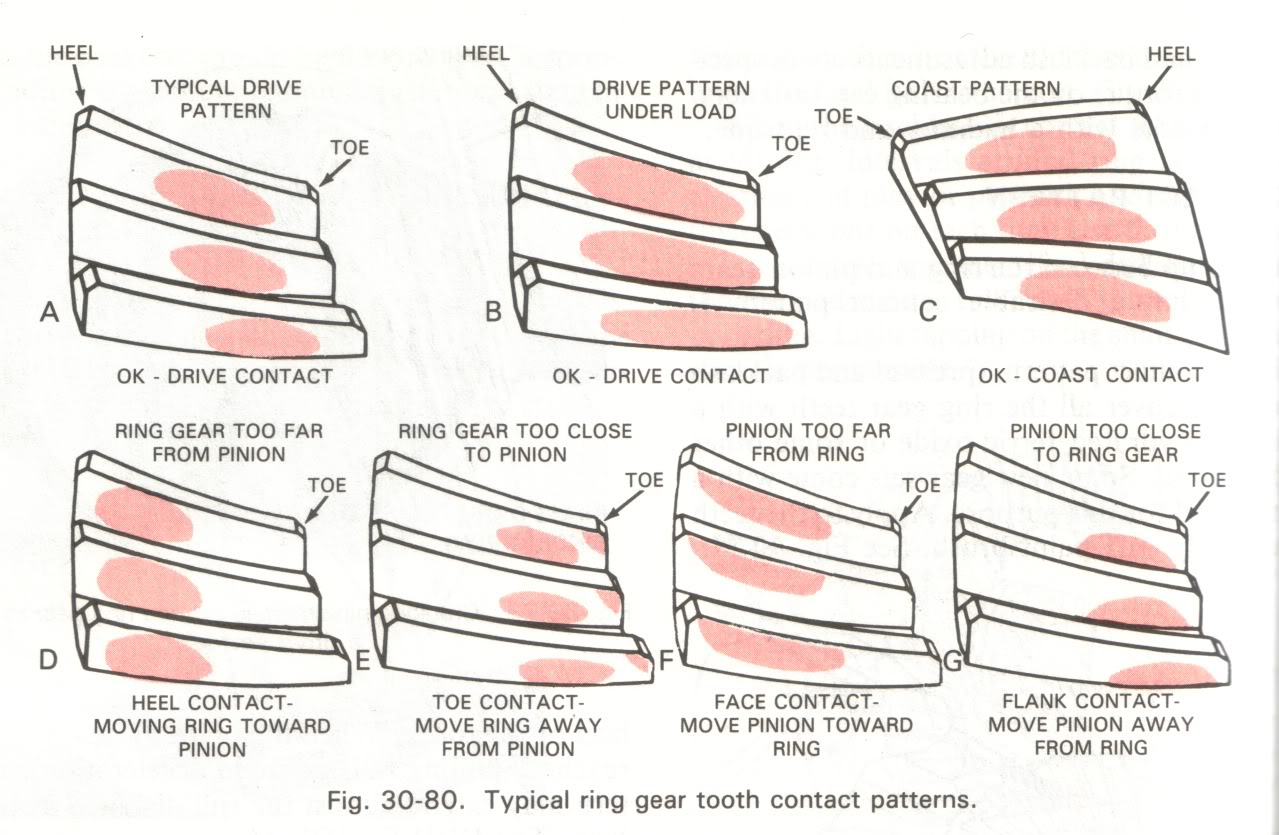

Gear Contact Pattern Paint - The package came today but they forgot to throw in the gear marking compound:shaking:. To check the contact pattern, apply marking compound to the ring gear teeth and run the gears under load. In this video we give a quick d. I actually don't use that, but it's very obvious to see in that pic. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web gear tooth contact pattern. If your gear tooth pattern looks like the photo above, you have a perfect gear tooth pattern. A contact pattern closer to the gear face means the pinion is too far away from the ring gear. Drive pattern should be well centered on ring gear teeth. Web i ordered bearings, shims, and the whole works to set up my gears. To check the contact pattern, apply marking compound to the ring gear teeth and run the gears under load. Web gear tooth contact pattern. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. That's where the teeth are contacting most. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. Web i ordered bearings, shims, and the whole works to set up my gears. Web one of the most common questions we're asked is how to properly read contact patterns when setting up a ring and pinion gear set. Second, it can prevent rust and corrosion from happening to the gears. A contact pattern closer to the gear face means the pinion is too far away from the ring gear. Gear tooth patterns are harbingers… they can foretell whether your ring and pinion gear set is going to live a long and prosperous life or if it’s doomed to an impending catastrophic failure. Web one of the most common questions we're asked is how to properly read contact patterns when setting up a ring and pinion gear set. Web paint ring gear with marking compound and roll the gear to obtain a contact pattern as shown in the photograph. Ring and pinion gear pattern is one of the most valuable tools for determining. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. Web best gear contact pattern paint is necessary for a few reasons. Get deals on automotive parts, truck parts and more. Web paint ring gear with marking compound and roll the. Web gear tooth contact pattern. If you use a rag to create drag on the ring and spin the pinion yoke in both directions, this will help the pattern come through better too. Then, roll the teeth through mesh so the compound transfers the. Web proper contact patterns between ring gear and pinion gear teeth are important for quiet gear. To correct the pattern, move the pinion toward the ring gear centerline. Web if practical, record tooth contact patterns under either loaded or unloaded conditions. Paint ring gear teeth with marking compound. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. Web gear tooth contact pattern. Web one of the most common questions we're asked is how to properly read contact pattern markings during differential gear setup. Web one of the most common questions we're asked is how to properly read contact patterns when setting up a ring and pinion gear set. Web a contact pattern centered from face to flank indicates the correct pinion depth.. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns. First, paint can help protect the gears from wear and tear. Web a bright, dark yellow colored grease that is used to mark ring gear teeth to determine contact points. Web the gear contact pattern plays a crucial role in the performance and longevity of gears. In. Web i ordered bearings, shims, and the whole works to set up my gears. Web the gear contact pattern plays a crucial role in the performance and longevity of gears. Web the ideal gear tooth pattern will have the contact patch on both the drive and coast sides of the teeth centered between the face and the flank as well. Web the service tools will be used to establish the proper amount of shims required prior to installing the pinion gear. Second, it can prevent rust and corrosion from happening to the gears. Web gear tooth contact pattern. We'll show you how to apply marking compound, and what to look for in the resulting. The images below illustrate both acceptable. Web best gear contact pattern paint is necessary for a few reasons. Web yellow or white compound grease paint to help see the pattern then mix it with a few drops of gear oil mix it and the compound will go further and spread cleaner to see the contact pattern. I actually don't use that, but it's very obvious to. Web the ideal gear tooth pattern will have the contact patch on both the drive and coast sides of the teeth centered between the face and the flank as well as the toe and the heal. By understanding, analyzing, and optimizing the gear contact pattern, manufacturers can ensure reliable and efficient gear operation. Web one of the most common questions. Web the gear contact pattern plays a crucial role in the performance and longevity of gears. Get deals on automotive parts, truck parts and more. Web how to create & read ring gear patterns. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. First, paint can help protect the gears from wear and tear. Web a bright, dark yellow colored grease that is used to mark ring gear teeth to determine contact points. Web you can see at the bottom right of your contact, the paint is almost completely gone in the second tooth. Web best gear contact pattern paint is necessary for a few reasons. Begin by setting proper pinion bearing preload, total turning preload, and ring gear backlash. Then, roll the teeth through mesh so the compound transfers the. Web a contact pattern centered from face to flank indicates the correct pinion depth. Coast pattern should be centered, but may be slightly toward toe of ring gear teeth. Paint ring gear teeth with marking compound. That's where the teeth are contacting most. Web one of the most common questions we're asked is how to properly read contact patterns when setting up a ring and pinion gear set. To correct the pattern, move the pinion toward the ring gear centerline.Weber Ring Gear Contact Pattern Interpretation Gear Tooth

Reading Gear Paint Patterns.. NASIOC

Reading Gear Paint Patterns.. NASIOC

20+ Gear Contact Pattern Paint GerardoNeoma

Best Gear Contact Pattern Paint A Comprehensive Guide

20+ Gear Contact Pattern Paint GerardoNeoma

Ring paint/ pinion IH8MUD Forum

ring gear contact pattern 2 YouTube

Once backlash is within spec you can set the pinion depth by reading

Fig. 1 Drive Axle Gear Tooth Pattern s

If You Use A Rag To Create Drag On The Ring And Spin The Pinion Yoke In Both Directions, This Will Help The Pattern Come Through Better Too.

If Your Gear Tooth Pattern Looks Like The Photo Above, You Have A Perfect Gear Tooth Pattern.

A Contact Pattern Closer To The Gear Face Means The Pinion Is Too Far Away From The Ring Gear.

Web Jegs Gear Marking Compound | 1/2 Ounce Size | Includes Application Brush | Made In Usa | Confirms Gear Wear Pattern Insuring Proper Installation

Related Post: